Lifting non-porous materials, such as glass, polished stones, and certain types of plastics and metals, presents a unique set of challenges due to their smooth, air-impermeable surfaces. Traditional handling methods often fall short, either because they cannot securely attach to the surface or because they risk damaging the material.

This article will explore the most effective techniques and tools for lifting non-porous materials, focusing on innovations and practices that ensure safety, maintain material integrity, and enhance operational efficiency.

By understanding the characteristics of these materials and the suitable handling mechanisms, industries can significantly improve their processes and reduce the risk of damage and accidents.

How to leverage technology for control and precision?

The integration of advanced technology further enhances the capabilities of lifters for non-porous materials. Modern vacuum lifters are often equipped with sophisticated sensors and control systems that allow for precise handling and placement of materials.

These systems can adjust the suction force based on the load’s weight and the type of material, ensuring optimal grip without exerting excessive pressure that could damage delicate surfaces.

Additionally, programmable logic controllers can be used to automate the lifting process, coordinating with other automated systems to optimize the workflow. This level of automation not only increases efficiency but also reduces human error, ensuring consistent handling and reducing the likelihood of accidents or material damage.

What do you need to know about specialized equipment?

For lifting non-porous materials, specialized equipment known as lifters is crucial. As suggested by Central Platform Services Ltd, these devices are specifically designed to handle the unique challenges posed by smooth, non-porous surfaces.

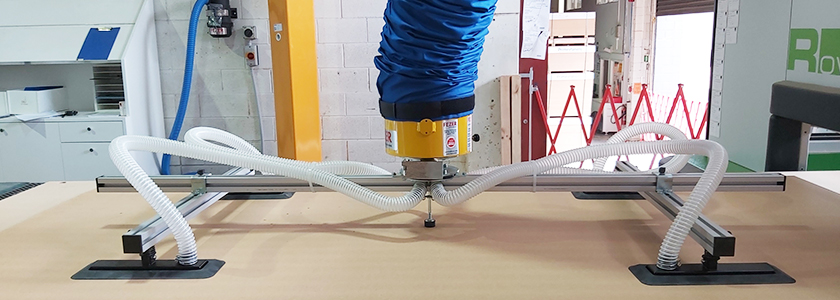

One of the most common and effective types of lifters used in such applications is the vacuum lifter. Vacuum lifters work by creating a strong suction force between the lifter and the material, securely adhering without the need for physical penetration or adhesive bonds.

Vacuum lifters come in various designs, tailored to different sizes, shapes, and weights of materials. They can be manually operated or fully automated, depending on the application’s complexity and precision required.

The key advantage of using vacuum lifters is their ability to handle large, heavy, or awkwardly shaped non-porous items with ease and precision. Additionally, since they do not require clamping or adhesive, there is no risk of damaging the material’s surface, making them ideal for industries where material integrity is paramount.

What do you need to do to ensure efficiency and safety?

When deploying lifters for non-porous materials, several safety and efficiency considerations must be kept in mind to ensure optimal operation. Firstly, it is crucial to regularly inspect and maintain the equipment, especially the suction components, to ensure they remain clean and functional. Any leaks or wear can reduce the effectiveness of the vacuum and potentially lead to failures, posing safety risks to operators and damage to the materials.

Operators must also be adequately trained in the use of these lifters. They should understand the mechanics of the devices, the correct operating procedures, and the safety protocols to prevent accidents. Furthermore, when setting up lifting systems, it’s essential to consider the environment in which they will operate.

Factors such as temperature, humidity, and air quality can affect the performance of vacuum lifters, so conditions should be controlled or monitored where possible.

How to integrate different processes and systems?

In many industrial applications, lifting non-porous materials is only one part of a larger material handling system. Therefore, integrating specialized lifters with other equipment and workflows is crucial for maintaining efficiency and throughpu

For instance, vacuum lifters can be mounted on overhead cranes or gantry systems to move materials through different stages of production or construction seamlessly.

This integration not only speeds up the handling process but also reduces the need for manual labor, lowering the risk of injuries and improving overall workflow efficiency.

Additionally, with advancements in robotics and automation, vacuum lifters can be incorporated into fully automated systems, allowing for precise and consistent handling around the clock, which is particularly beneficial in high-volume manufacturing environments.

What are the customization options?

Given the variety of non-porous materials and the specific requirements of different industries, the ability to customize lifters is crucial. Manufacturers of lifting equipment often offer bespoke solutions, designing lifters that are tailored to the size, shape, and weight specifications of the materials to be handled.

This customization can include adjustable suction pads, multi-angle capabilities, and modular components that can be swapped out or adjusted as needed.

Customized lifters not only improve the safety and efficiency of material handling but also ensure that the equipment can adapt to different tasks or changes in production requirements without needing complete replacement.

This adaptability makes them a valuable long-term investment for businesses that deal with a range of non-porous materials.

How to maintain the safety and reliability of your tools?

To maintain the reliability and safety of lifters for non-porous materials, a rigorous maintenance schedule is essential. Regular checks should be made to ensure that all components, especially the suction mechanisms, are in good working order.

The seals, filters, and pumps that support the vacuum must be inspected for wear and tear and replaced as necessary to prevent failures that could lead to drops or slips, endangering workers, and damaging materials.

Proper training for all personnel who operate or maintain the lifting equipment is just as important as the maintenance itself.

Training should cover not only the basic operation of the lifters but also troubleshooting, emergency procedures, and understanding of how changes in the environment (such as temperature and humidity) can affect the equipment’s performance.

This comprehensive training ensures that workers are prepared to handle the equipment safely and respond effectively to any issues that may arise.

Choosing the best way to lift non-porous materials involves a combination of selecting the right equipment, integrating advanced technologies, and ensuring proper maintenance and training.

Vacuum lifters, particularly when customized and integrated into broader automated systems, offer an effective solution for safely and efficiently handling delicate non-porous materials.

By investing in high-quality lifting solutions and prioritizing ongoing maintenance and training, industries can enhance their operations and maintain high standards of safety and precision in their material handling processes.

This strategic approach not only improves productivity but also helps protect valuable materials and the well-being of workers, contributing to the overall success of the organization.